Pitch servo positioning and hardpoints | 1.20.2021

Also in the shipment from Velocity the other day was our autopilot elevator arm, so I began work on positioning and installing the autopilot pitch servo.

This install was a bit tricky, because with the relatively small throw of the Garmin (and other newer) servo arm, the geometry gets a bit odd. Basically, this needed to be positioned pretty far back on the canard to get the full throw without hitting the Garmin overcenter protection bracket. I also had to carve out some of the trailing edge of the canard to make room for the linkage, with how low on the elevator bracket it had to be mounted to get the full throw.

|

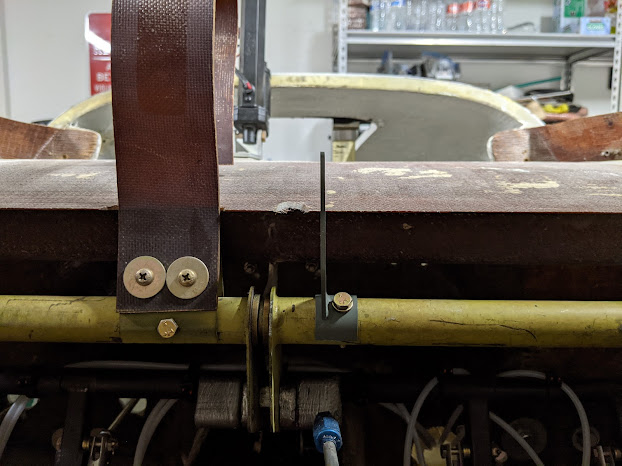

| Here's the elevator arm (right) drilled and secured. I put this just outside of the bushing that's inside the torque tube in the middle. |

Once everything was positioned and I was confident that the geometry would work (1.5 hrs later...), i mixed up some structural adhesive with cabo and adhered the hardpoints in.

|

| Duct tape holds everything in place. Also this wasn't moving anyway. |

|

| Here's how close to the trailing edge the hardpoints had to be to get the approach angle right. Also note how low the elevator arm is drilled to be able to get the full throw with the autopilot. |

While I had some structural adhesive whipped up, I also took the opportunity to adhere a hinge to the oil access door. One of those things I just keep forgetting to do.

|

| Oil access door |

That's it for now!

- Jeff

Comments

Post a Comment