Heater flapper install, intake tube mods | 1.31.2021

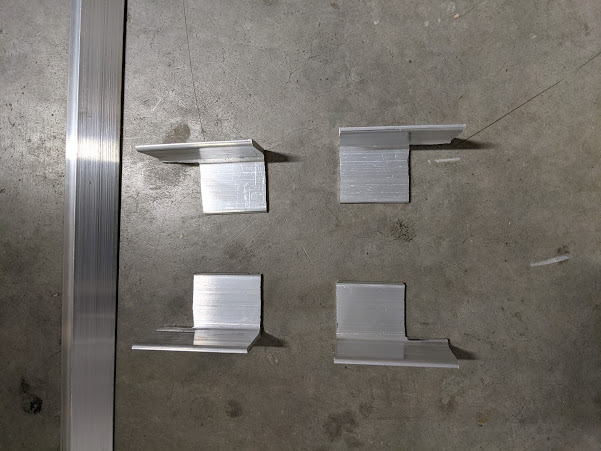

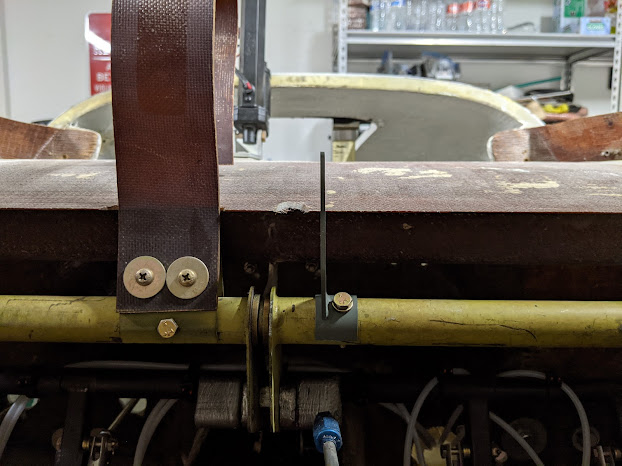

Finally got around to installing the heater flapper control. Basically needed to mount the control, route it through the canard bulkhead, and connect. Started by fabricating the hardpoints and figuring out the mounting location. The best mounting location I could come up with was on the pilot's left hand side on the fuselage. Since the control would need to be canted out, I made the front mounting point out of 1" (if I'm remembering right?) square aluminum. I then installed a nutplate in this. The control was then installed to the hardpoints with adel clamps, and the hardpoints were structurally adhered to the fuselage and secured to the fuselage to cure with rivets. Ready to adhere. Installed location. I then routed the cable through an existing hole in the bulkhead. Not the most optimal location, but I wanted to use an existing hole rather than make another. The cable was trimmed to length, and the rest of the hardware was installed per plans. Works great! I then start