Started the evening by attaching the additional elevator balance weights to the elevator per the new Velocity recommendation. To get the elevator to balance properly, I also added more weight on the center as well. Used the other "half" that was cut from the outboard weights. This is off-plans, but needed to balance out. I guess I have a slightly heavier than normal elevator.

|

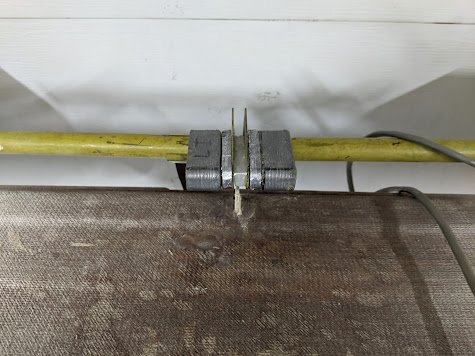

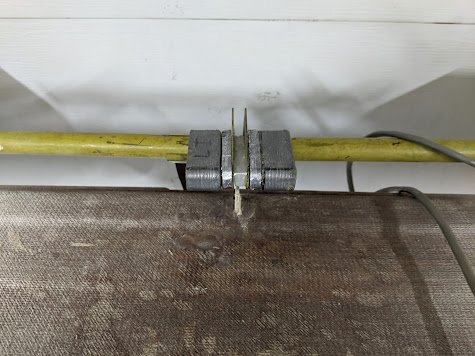

Center weights, with extra.

|

|

Outboard weights

|

|

Will need to notch into the canard tips to make room for the added weight.

|

|

Weights slightly more than needed right now. This will balance out when final paint is applied to elevator.

|

With the counterweights on the elevator done, I moved to the nose gear strut... again. Re-installed the longer strut... again, and attempted all sorts of adjustments after talking to Scott Swing. Nothing worked; the geometry of the gear system with the ever so slightly longer strut just doesn't work.

As an illustration of just how little difference this is: old strut (center to center) is 209mm. The beefier strut is 215mm. About a quarter of an inch.

I gave up and decided that I'd send the two struts back to the factory where they have a jig and they could swap the stronger spring onto the shorter strut. Away they went back to Velocity. We had the engine install kit coming soon, and they could just toss the fixed one in with that stuff to save shipping.

At this point, I re-installed the aluminum bar and everything cycled great. As a side note, at this point the gear has been cycled 30+ times since the cylinder rebuild and no leaks or issues.

|

What it looks like with no strut in place.

|

|

Re-installing the strut, thinking I could make it work for the umpteenth time.

|

|

| Annnnnnnnnd, aluminum bar is back in... |

|

|

|

|

|

Comments

Post a Comment