Micro filler, door hardware | 10.29.2020 - 10.30.2020

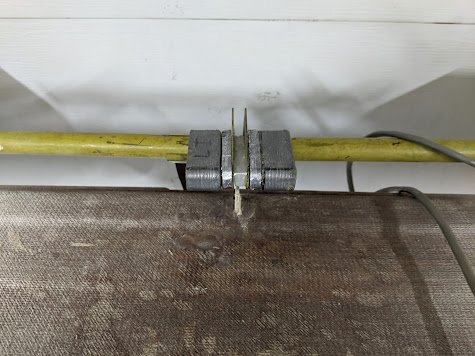

On the 29th, Micro-bubble was applied around the nose scoop to fair it in. Also hit some other areas that needed filled. This will get sanded later. Yay sanding. On the 30th, Emily and I worked on getting all the door hardware situated. On the co-pilot's side, that included lining up and drilling for the roll pin on the co-pilot's security lock. I didn't have a roll pin around, so had to order one and set it aside. Hole drilled for roll pin later. Helpful diagram in background. Also finished the cotter pins since they were all half-bent awaiting the security lock install. Each of the bars shown goes to one of the door pins that holds the door securely in place when locked for flight. Cotter pins done From there, we moved on to installing the pilot's side lock cylinder. This turned out to be a huge pain to get centered from the back side and held in place. First, the lock body is ground down to sit behind the outer door skin. This is then glassed in place from the inside...